08.01.2024

The principle of operation of the DeltawaveC ultrasonic flowmeter is based on measuring the difference in the transit times of the ultrasonic wave. In the absence of flow, the wave transit times in both directions are the same. When the wave propagates against the direction of the flowing liquid, the propagation speed is slower than in the direction consistent with the movement of the liquid.

To measure flow with DeltawaveC, two ultrasonic transducers are mounted outside the pipe and connected to the transducer. Ultrasonic probes work alternately as a sender and receiver and transmit ultrasonic signals to each other, while the signal durations between the transmitted and returned signals are measured (t1, t2). In this process, the flow is measured many times, usually 50-150 times in one second. Due to this high number of measurements, but also due to the use of the latest digital signal processors, DeltawaveC operates reliably, even in very dynamic and difficult process conditions.

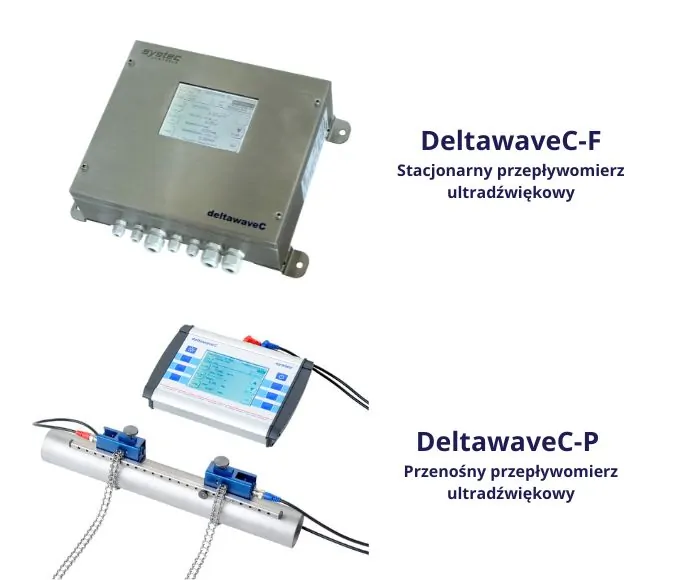

Non-invasive DeltawaveC flowmeters in stationary and portable versions.

Non-invasive DeltawaveC flowmeters in stationary and portable versions.The DelawaveC ultrasonic flowmeter is available in a stationary version (DelawaveC-F) and a portable version (DelatwaveC-P). DeltavaweC-P, thanks to the built-in battery power supply, is used for portable flow measurements for process control, but can also be used for measurements over a longer period of time. Battery life is approximately 12 hours. In turn, DelatwaveC-F is intended for permanent installation and continuous measurement and recording of flows.

The stationary DeltawaveC-F can optionally have a second measurement channel. In this way, it is possible to measure two installations with one device or equip one installation with two measurement paths.

Both versions of the flowmeter can be expanded to measure the amount of heat used. This is a big advantage of these devices, considering the rising energy prices and increasingly restrictive regulations regarding environmental protection and installation efficiency. Therefore, continuous optimization of energy flows becomes necessary, and DelatwaveC flow meters can help with this.

Both DelawaveC-P and DelawaveC-F are easy to install. These are non-invasive flow meters - it is not necessary to interfere with the pipelines or stop the processes during their installation. Thanks to this, DelatwaveC ultrasonic flowmeters contribute to the optimization of operating costs. The quick device configuration option allows you to set parameters within a minute. A clear display in Polish, English or German makes it easy to read the information. The menu is clear and operating the device using 8 buttons is very simple.

DeltawaveC will be used in many industries, including: power plants, water and sewage management, building technology, chemical, petrochemical and food industries.

If you are interested in ultrasonic flowmeters – check out the possibilities of DeltawaveC-P orDeltawaveC-F.

10.02.2026

The Warsaw HVAC Expo is an opportunity to learn about cutting-edge technologies, innovative products, and solutions in heating, ventilation, and air conditioning. One of the exhibitors showcasing its offerings this year will be Regin. Poltraf is the exclusive distributor of Regin in Poland.

20.12.2023

A pressure transmitter is a commonly used device that converts the pressure value into an appropriate output signal. The signal from the pressure transmitter is read and forwarded to the control system. In times of shrinking fossil fuel resources, looking for alternative energy sources is a necessity. Hence the increasing popularity of hydrogen, which is the most common element in the Universe and one of the most common elements on Earth. However, not every pressure transmitter can be used to work with hydrogen. Why is it like that? Which sensor technology in the pressure transmitter is best for this medium? We answer these questions below.

04.09.2023

The Swiss company Belimo is a world leader in the production of devices for energy-efficient control of heating, ventilation and air-conditioning systems. It specializes in the production of innovative actuators for dampers, control valves, sensors and counters. Familiarize yourself with our offer of Belimo air damper actuators.

We are a representative and distributor in Poland of the following brands: