07.11.2025

Electromagnetic Flowmeter Design

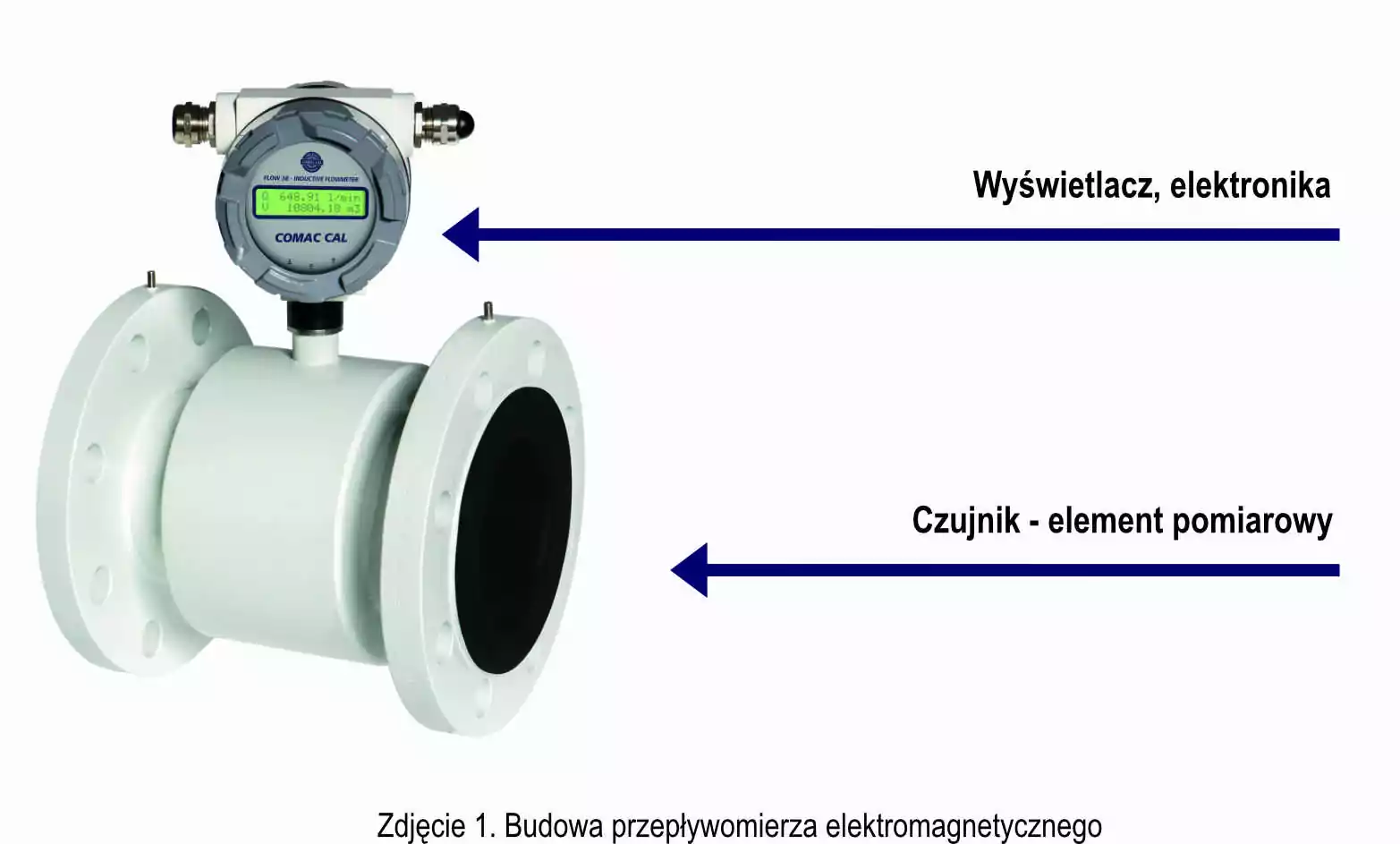

To understand the causes of errors when designing and selecting electromagnetic flowmeters, it is first necessary to understand the design and operating principle of the flowmeter. Electromagnetic flowmeters consist of two parts: a sensor mounted on the pipe and electronics that process the signal from the sensor (photo 1).

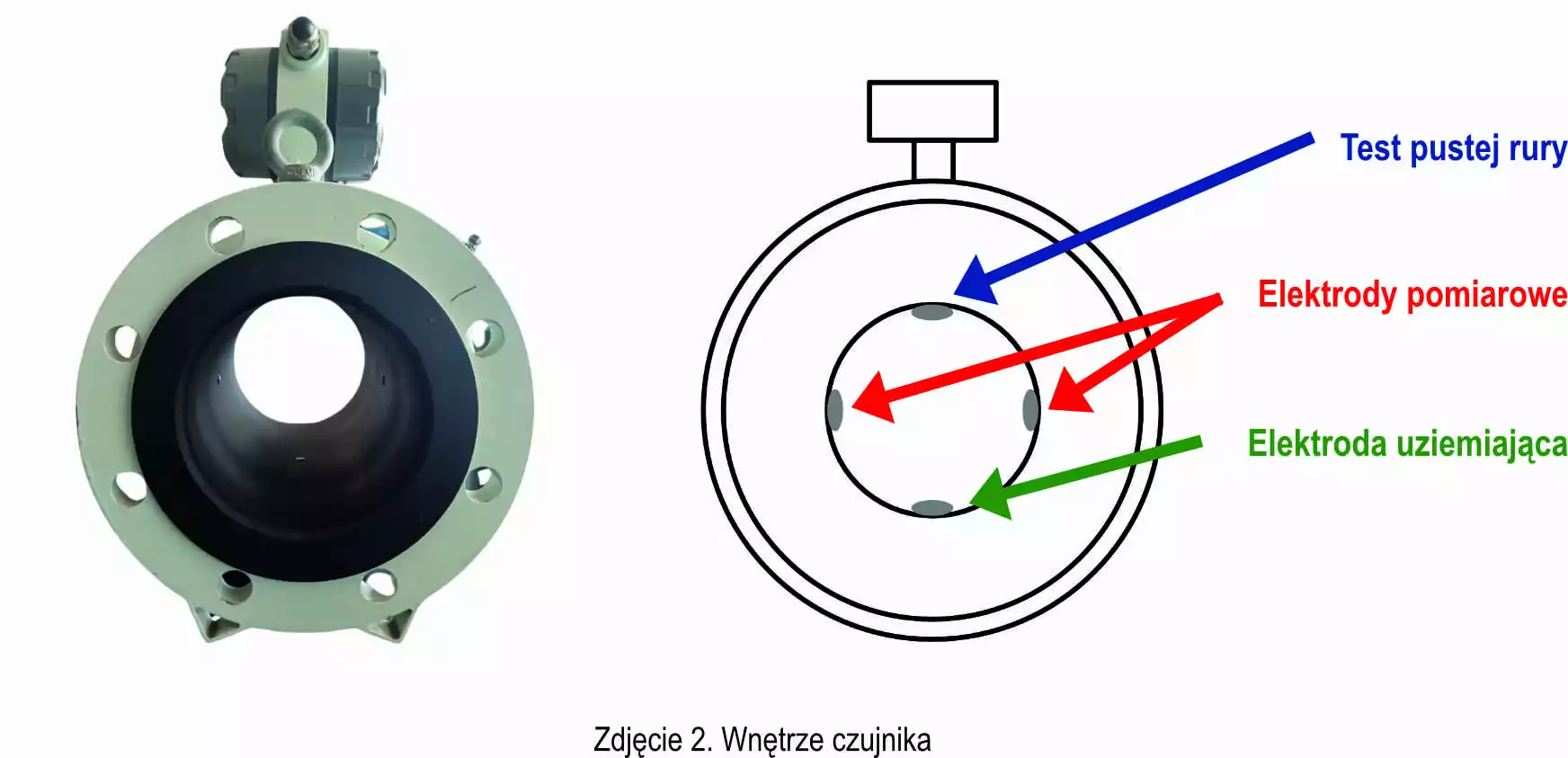

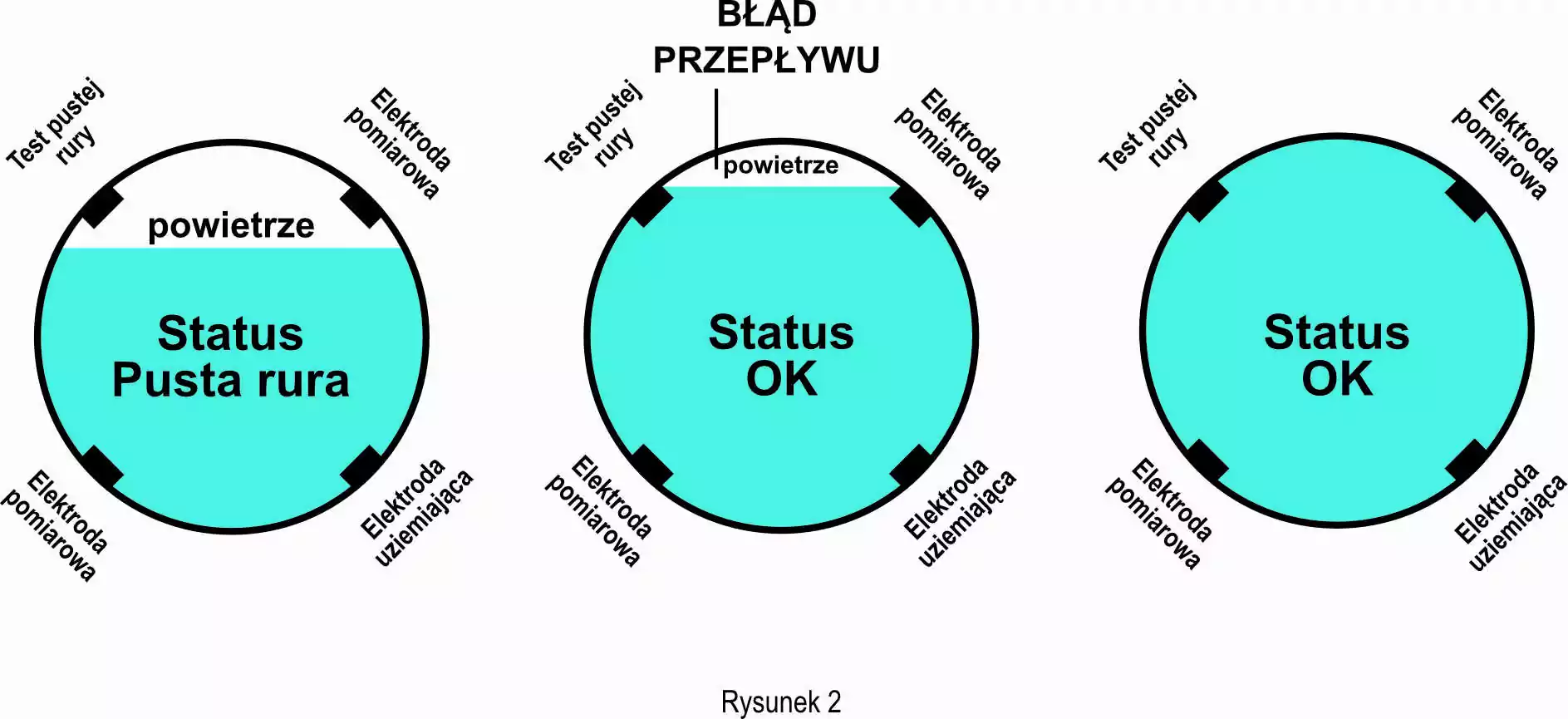

There are 4 electrodes inside the sensor: two measuring electrodes placed horizontally, the lower one for grounding and the upper one responsible for detecting whether the pipe is full, i.e. the so-called empty pipe test (photo 2).

The operating principle of an electromagnetic flowmeter is based on the Faraday effect, which allows an electric current to be generated using a magnetic field. Inside each flowmeter are two coils that generate a constant electromagnetic field. Electrically charged positive and negative fluid particles accumulate on opposite sides of the measuring electrodes as they flow, inducing a voltage. Two electrodes, installed at right angles to the electromagnetic field, measure the voltage (measuring electrodes). The greater the flow, the greater the voltage at the measuring electrodes.

It's the design and operating principle that define the ideal measurement applications for an electromagnetic flowmeter. They are used in numerous industries, including water, paper, pharmaceuticals, food, chemicals, and many others. This doesn't mean that these devices can be used without any problems in every application. What's most important to remember? The liquid being measured must be conductive, meaning it conducts electricity and contains both positive and negative particles. The minimum required conductivity is 20µS. This is necessary to induce a voltage at the measuring electrodes. This phenomenon won't occur with dielectric liquids. Therefore, these devices are not suitable for measuring demineralized water, fuels, paints, polymers, etc. However, they are ideal for measuring the flow of water (clean, dirty, swimming pool water, etc.), juices, beer, chemicals, and many other liquids. In turn, because the flow meters have no moving parts and the surface inside the flow meter is almost perfectly even, we can measure liquids containing solids, such as sewage, as well as fruit and paper pulp or even concrete.

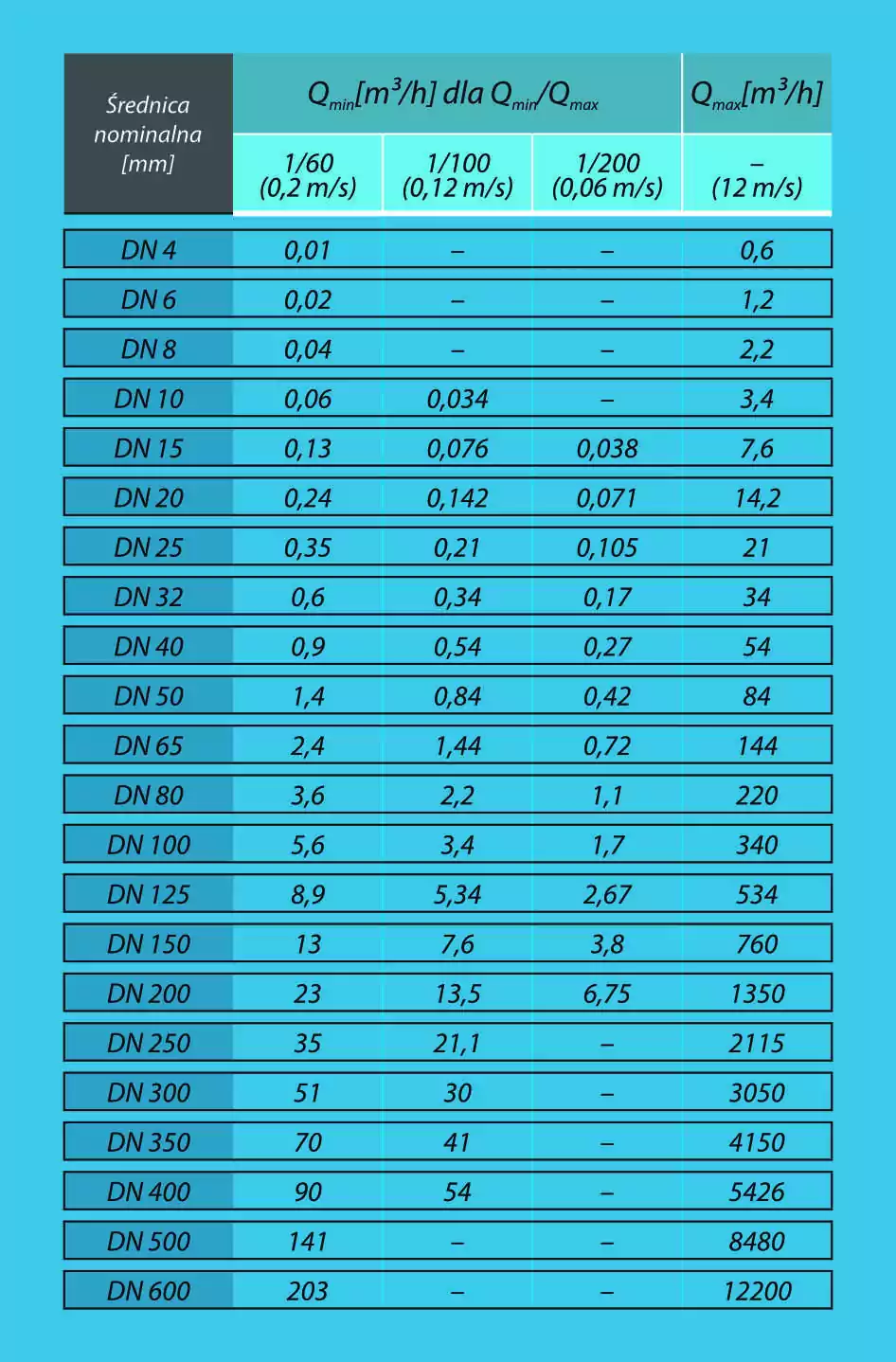

Regardless of the medium being measured and its conductivity, an appropriate flow velocity is necessary to generate a voltage at the measuring electrodes. To achieve adequate measurement quality, i.e., with a maximum measurement error of 0.5%, a flow rate of 0.2 m/s is recommended. This represents 1/60th of the maximum flow rate we can measure, i.e., 12 m/s. The table below shows how this translates to m³/h. In certain diameters, it is possible to increase the flowmeter's sensitivity for minimum flow rates to 1/100th or even 1/200th of the maximum rate, i.e., 0.12 m/s or even 0.06 m/s. It should be noted that flow values in m³/h refer to a uniform flow over a full hour. For example, if we have a flow of 5 m³/h, but it only flows for 10 minutes of the hour, we actually have an average flow of 30 m³/h, and the flowmeter's measurement range should be selected accordingly.

The above indicates that we are measuring the flow rate of a fluid in a pipeline, and the volume is proportionally converted from m/s to m³/h based on the pipeline cross-section. Therefore, for accurate measurement, the medium MUST flow through the full pipe. This applies to classic electromagnetic flowmeters, not special versions with level measurement, which calculate flow proportionally based on the fill level. In standard electromagnetic flowmeters, free space will constitute a measurement error. The empty pipe test electrode is used to eliminate this error.

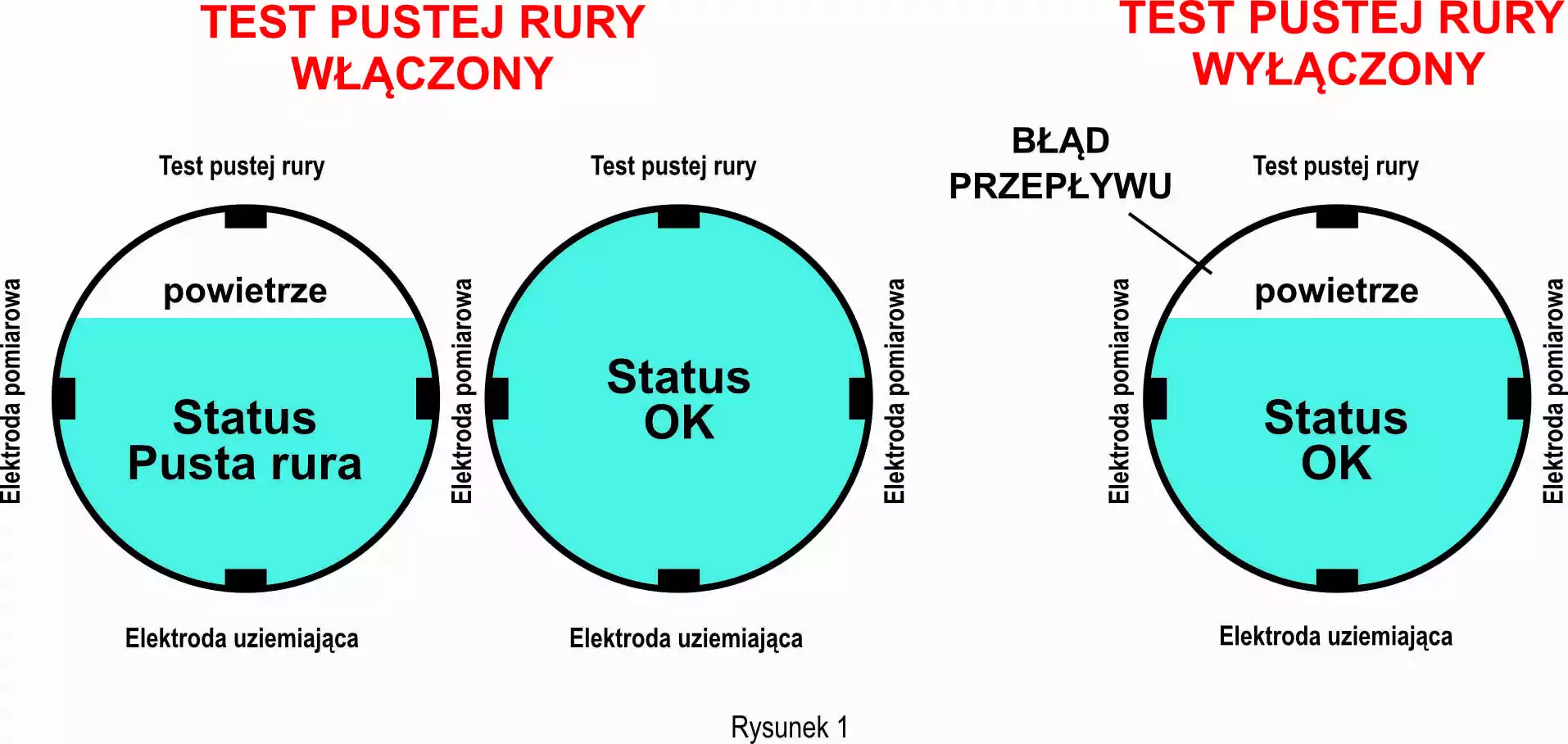

How does this work? When the measuring electrode mounted at the top of the flowmeter "contacts" the medium, we receive information that the medium is flowing through a full pipe. If the empty pipe test is enabled and the electrode is in contact with the medium, the flowmeter will display the status: Empty Pipe Test OK. If there is no contact with the medium, the main screen will display the message: "Attention! Empty pipe!" and the flowmeter will automatically stop measuring. We can also disable the empty pipe test and assume that the medium always flows through the full cross-section of the pipe, and any empty space will constitute a measurement error. It is important to remember that the flowmeter will only stop measuring when the medium level drops below the measuring electrodes, i.e., below 50% fill level.

Sometimes, the lack of fullness is acceptable to the user to a certain extent. In such cases, users install the flowmeter with one screw offset on the flanges, which means that the electrode responsible for the empty pipe test is not perfectly positioned at the top of the pipeline, and a certain free space with the full pipe test enabled will be displayed as an empty pipe: OK (Figure 2 - middle diagram). This free space will constitute our excessive measurement error. Only a drop in the level below the test electrode will cause an error and stop the count.

It's also worth considering the various sensor materials available, as well as the liner itself. Before purchasing a flowmeter, it's crucial to specify the medium it will be measuring. Properly selecting materials will ensure long-term, trouble-free operation. We have a comprehensive list of material compatibility for both the flowmeter liner and electrode materials. In addition to the most popular rubber liner, we also offer Teflon (PTFE, ETFE), mesh-reinforced Teflon (PFA), and ceramic liner options. Standard electrodes are made of SS316Ti stainless steel, and optional electrodes made of materials such as Hastelloy C4, titanium, or tantalum are available for the most demanding applications.

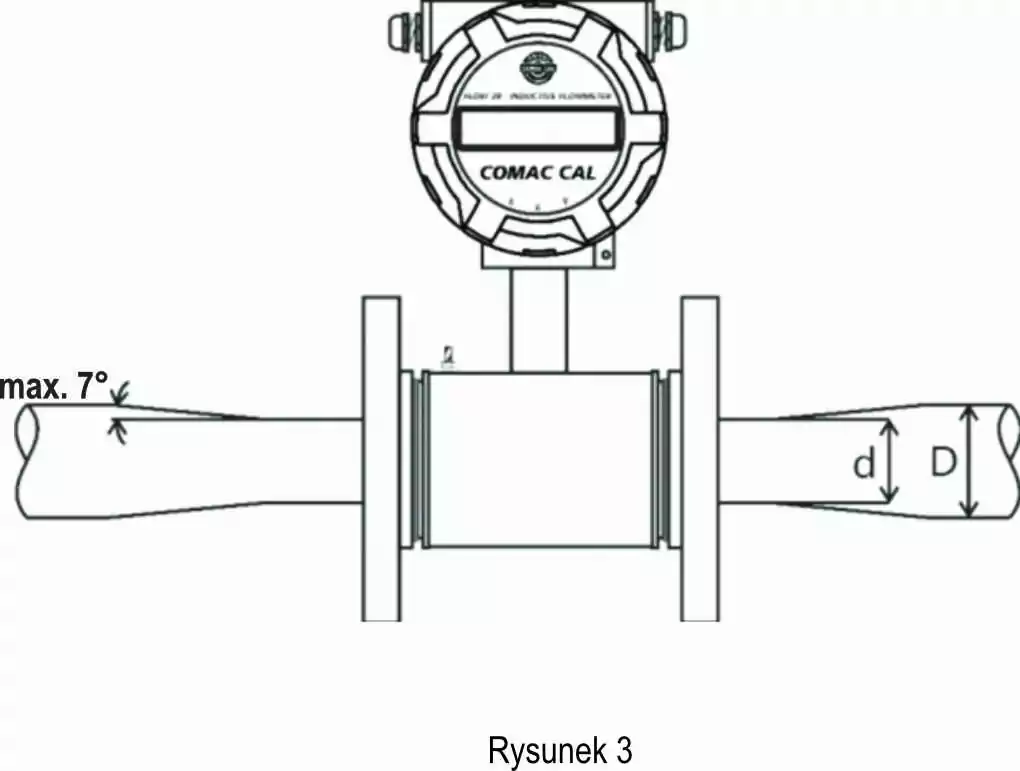

Returning to the issue of ensuring proper fluid flow through the pipeline, i.e., ensuring adequate filling and minimum flow velocity, it is best to use a flowmeter in applications with forced (pump) flow. Here, too, it's worth selecting the nominal flow rate within 20%-80% of the measurement range, leaving some margin for non-standard, periodic flows outside this range. To this end, it's good practice to tape the pipeline so that the flow is faster and flows through the full pipe. When tapering the pipeline, remember that the taper angle should not exceed 7° (Figure 3).

If flow restriction is not possible, we can increase the flow sensitivity to 1/100 of the maximum flow rate (for diameters from DN10 to DN400) or even to 1/200 (for diameters from DN15 to DN200). Importantly, a medium flow rate below the minimum measurement rate will not stop the measurement, but will only result in a measurement with a slightly larger measurement error, around 1-2%, than the standard 0.5%.

Our offer includes electromagnetic flowmeters from the Flow series by Czech manufacturer Comac Cal. The most popular is the classic Flow 38 electromagnetic flowmeter, which is also available with an MID. An IoT telemetry module is available for the Flow38, enabling remote access to measurement data via a web platform.

Another popular electromagnetic flowmeter model is the battery-powered Flow45 electromagnetic flowmeter. This year's new product is the Flow55 for pipes that are not fully filled. Check out the Flow series electromagnetic flowmeters in our online store at czujniksterowniki.pl.

Please note that the prices displayed in the online store are indicative for selected parameters. Due to the large number of possible combinations, please contact us for an accurate quote.

02.06.2025

The IoT module for the Flow38 electromagnetic flowmeter saves time and money.

We are a representative and distributor in Poland of the following brands: